Wisconsin companies owned by University of Wisconsin-Stout alumni have joined the battle to help keep health care and other essential workers safe during the COVID-19 pandemic.

Prent, a plastics thermoforming company, of Janesville and Franzen Graphics/Sun Media of Sheboygan have responded to the critical need for face shields by quickly developing new products at their facilities.

Prent, a plastics thermoforming company, of Janesville and Franzen Graphics/Sun Media of Sheboygan have responded to the critical need for face shields by quickly developing new products at their facilities.

Plastic face shields help protect someone’s full face, including their eyes, to supplement face masks that cover the nose and mouth.

Prent, with its sister company GOEX, has produced more than 30,000 face shields in Janesville and has given them away there and in Flagstaff, Ariz., and Yauco, Puerto Rico, three of the five cities where it has facilities.

The effort at Prent has involved about 10% of the company’s employees, according to Joe Pregont II, the son of CEO Joe Pregont, a 1981 industrial technology graduate with a minor in packaging. In 2018, Prent Packaging Laboratories were dedicated at UW-Stout.

The effort at Prent has involved about 10% of the company’s employees, according to Joe Pregont II, the son of CEO Joe Pregont, a 1981 industrial technology graduate with a minor in packaging. In 2018, Prent Packaging Laboratories were dedicated at UW-Stout.

Prent is a global leader in custom thermoform packaging for the medical, electronics and consumer industries.

“Everyone is aware of how critical these face shields are to the members of our community and the others we are shipping to, and it has created an eagerness to support the line in any way,” Pregont II said.

“Everyone is aware of how critical these face shields are to the members of our community and the others we are shipping to, and it has created an eagerness to support the line in any way,” Pregont II said.

Prent delivered its first face shields to Mercyhealth Hospital and Trauma Center in Janesville in 48 hours, two days ahead of schedule, after learning of the shortage. Workers developed several working models in four hours, using 3D modeling and a laser cutter. A supplier built a production die in five hours.

In Sheboygan, Franzen Graphics also has switched part of its production facilities to make face shields, quickly designing a one-piece product in two thicknesses. The company has had orders for tens of thousands of the shields, which it is selling at cost.

In Sheboygan, Franzen Graphics also has switched part of its production facilities to make face shields, quickly designing a one-piece product in two thicknesses. The company has had orders for tens of thousands of the shields, which it is selling at cost.

“At capacity, we anticipate we can produce about 10,000 a day, as long as the supply chain can deliver,” said company founder Nick Franzen, a 2006 UW-Stout graduate in business administration.

“It is a single part, no seams product that allows it to be cleaned very quickly and easily. The idea was to make an easy-assemble product, so we can ship fast, produce fast and keep cost low and still provide for critical personnel,” he said.

Priority customers are emergency services and essential personnel. Watch a video about the Franzen Graphics face shield. For information on how to order, call 1-800-236-2757.

Read the latest information about the UW-Stout and the COVID-19 situation.

###

Photos

Workers at Prent in Janesville make plastic face shields to help those involved the fight against the coronavirus pandemic. / Prent photo

Joe Pregont, UW-Stout alumnus and Prent CEO

Prent, led by a UW-Stout alumnus, had distributed more than 30,000 face shields. / Prent photo

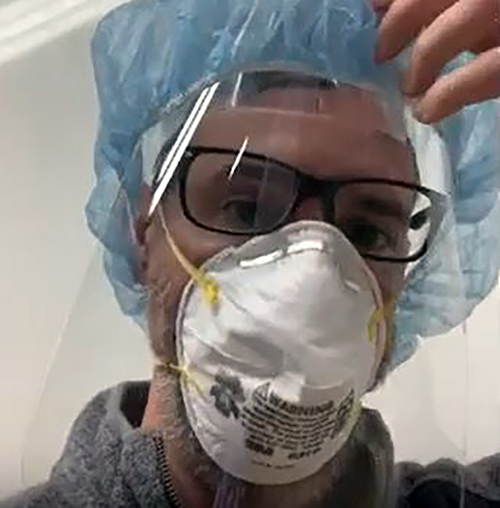

A worker at Franzen Graphics/Sun Media demonstrates a clear plastic face shield to help protect health care and other workers during the pandemic. The Sheboygan company, which is making up to 10,000 shields a day, was founded by a UW-Stout alumnus.